Introduction

The Tracked Radial Stacker is a high-performance, mobile material handling system designed to create efficient and large stockpiles of bulk materials. Combining radial movement with tracked mobility, this conveyor excels in environments where flexibility and stable operation on uneven terrain are required. The Tracked Radial Stacker is ideal for industries such as mining, aggregates, construction, and logistics, providing a reliable and efficient solution for bulk material stacking and stockpiling.

Application

The Tracked Radial Stacker is particularly beneficial in environments where high mobility, flexibility, and stability are crucial for efficient material stacking. It is used in various applications, including:

Mining

For stockpiling ores, coal, minerals, and other bulk materials, particularly in mines located on rugged or remote sites.

Aggregate Processing: Used to stack crushed stone, sand, gravel, and other aggregates in quarries, ensuring efficient material handling and stockpiling.

Construction

Ideal for stockpiling materials such as cement, asphalt, and earth-moving materials at construction sites with challenging ground conditions.

Ports and Terminals

Helps with bulk material handling and stockpiling of grains, fertilizers, or coal at loading docks and bulk terminals.

Recycling

Suitable for creating stockpiles of recyclable materials, optimizing space and streamlining material management at recycling facilities.

Design

Tracked Mobility

The Tracked Radial Stacker is equipped with heavy-duty rubber or steel tracks, providing superior traction and stability on uneven or challenging terrain. This feature makes it ideal for mining sites, quarries, and construction locations with difficult ground conditions.

Radial Movement

The conveyor is capable of 360-degree radial movement, allowing it to create large, conical stockpiles. This ability helps maximize storage space while minimizing material loss during handling.

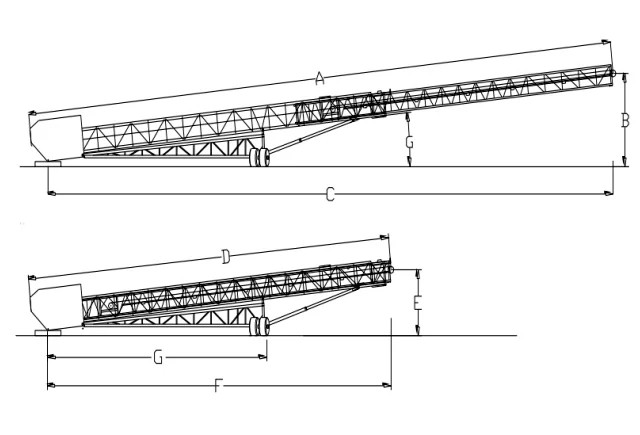

Telescopic Extension

The discharge height of the Tracked Stacker Conveyor can be adjusted to suit different applications. This feature is particularly useful for creating stockpiles of different sizes or when materials need to be transferred to specific locations.

Efficient Material Handling

The Tracked Stacker Conveyor is designed for high throughput, ensuring that bulk materials are transported and stacked efficiently. The design minimizes material spillage and reduces handling time.

Heavy-Duty Construction

The Tracked Stacker Conveyor is built with heavy-duty components to withstand the rigors of industrial use, providing a reliable and durable solution for material handling tasks.

Advantage

Heavy-Duty Steel Frame

The stacker's frame is made from high-strength steel to ensure stability and structural integrity, even under heavy loads and in harsh environments.

Abrasion-Resistant Conveyor Belts

These belts are designed to withstand wear from handling abrasive materials like gravel, coal, and minerals. Their durability ensures long service life and smooth operation.

Durable Track System

Rubber or steel tracks are utilized to provide excellent traction, allowing the stacker to operate smoothly over rough terrain without damaging the ground.

Corrosion-Resistant Coatings

Key components are coated with anti-corrosive materials to prevent rust and degradation from environmental exposure, ensuring long-term performance.

Safety Features

The conveyor is equipped with safety features, including emergency stop buttons, belt guards, and control protections, to ensure safe operation.

Production

Intelligent Production Workshop

Hebei, May 1st , 2023, JUXIN is thrilled to announce the triumphant completion and utilization of its state-of-the-art 6,000 square meter intelligent production workshop.

Intelligent Idler Production Line

Hebei, June 1st, 2023,JUXIN announces the successful implementation of its state-of-the-art Intelligent Idler Production Line.

Certificate

Hot Tags: tracked radial stacker, China tracked radial stacker manufacturers, suppliers, factory, Portable Tracked Stacker, Tracked Radial Stacker, Portable Radial Stacker, Tracked Stacker Conveyor, Radial Stacker Conveyor, Radial Telescopic Stacker

|

Model - Standard Model |

JTS7025 |

|

Length (m) |

25 (82.02ft) |

|

Capacity (t/h) |

200-500 |

|

Radial Stockpile Volume (t), 120 degrees |

10,530 |

|

Radial Stockpile Volume (t), 270 degrees |

20,930 |

|

Max. Discharging Height (m) |

9.3 (30.51ft) |

|

The reference density is 1.6t/m³. |

|

|

Model - Standard Model |

JTS7032 |

|

Length (m) |

32 (104.98ft) |

|

Capacity (t/h) |

500 |

|

Radial Stockpile Volume (t), 120 degrees |

20,975 |

|

Radial Stockpile Volume (t), 270 degrees |

42,105 |

|

Max. Discharging Height (m) |

10.5 (32.97ft) |

|

The reference density is 1.6t/m³. |

|

|

Model - Standard Model |

JTS3042 |

|

Length (m) |

42 (137.79ft) |

|

Capacity (t/h) |

500-1000 |

|

Radial Stockpile Volume (t), 120 degrees |

45,345 |

|

Radial Stockpile Volume (t), 270 degrees |

91,785 |

|

Max. Discharging Height (m) |

13.6 (44.61ft) |

|

The reference density is 1.6t/m³. |

|

|

Model - Standard Model |

JTS5042 |

|

Length (m) |

42 (137.79ft) |

|

Capacity (t/h) |

1200-3000 |

|

Radial Stockpile Volume (t), 120 degrees |

50,390 |

|

Radial Stockpile Volume (t), 270 degrees |

101,455 |

|

Max. Discharging Height (m) |

14.6 (47.90ft) |

|

The reference density is 1.6t/m³. |

|

|

Model - Standard Model |

JTS5051 |

|

Length (m) |

51 (167.32ft) |

|

Capacity (t/h) |

500-3000 |

|

Radial Stockpile Volume (t), 120 degrees |

81,890 |

|

Radial Stockpile Volume (t), 270 degrees |

166,145 |

|

Max. Discharging Height (m) |

17.5 (57.41ft) |

|

The reference density is 1.6t/m³. |

|

|

Model - Standard Model |

JTS5058 |

|

Length (m) |

58 (190.28ft) |

|

Capacity (t/h) |

200-3000 |

|

Radial Stockpile Volume (t), 120 degrees |

115,050 |

|

Radial Stockpile Volume (t), 270 degrees |

234,365 |

|

Max. Discharging Height (m) |

19.6 (64.30ft) |

|

The reference density is 1.6t/m³. |

|

|

Options For Portable Telescopic Stacker Conveyor |

|

25-58m (Customized Length) |

|

Fully Automatic PLC Stockpiling Program |

|

Radio Remote Control System |

|

Integrated Generator for Fully Independent Unit |

|

Fully Sealed Feed-in / Transfer and Discharge Points to Eliminate / Reduce Spillage On Site |

|

Dust Suppression Measures: Dust Covers, Dust Extraction, Rubber 'sock' Chutes, Water Suppression and Many More. |

|

Belt Update |

|

Idlers and Pulleys |

|

250 Micron Paint Finish |

|

Fully Mobile Tracked / Wheeled or Unrivalled Mobility On Site |