Introduction

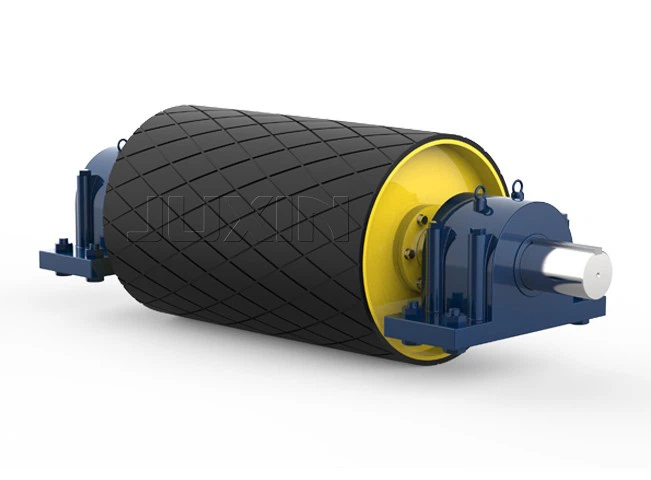

The head drive pulley serves as the primary head pulley in conveyor systems, transmitting motor power to drive belts and materials. Engineered with ceramic pulley lagging or rubber surfaces, it prevents slippage under heavy loads while enabling ferrous material separation. This dual-function assembly ensures reliable material handling in mining, cement, and logistics operations.

Application

Mining

Head drive pulley handle coal/iron ore transport in high-impact zones; ceramic pulley lagging withstands >50mm lump abrasion while extracting tramp metal.

Metallurgy

As the critical head pulley in conveyor lines for 800°C steel strips, tungsten-carbide coatings maintain ±2mm alignment during magnetic material sorting.

Cement

PTFE-coated head drive pulley prevent salt adhesion in fertilizer plants, with corrosion-resistant protecting downstream equipment.

Chemical

PTFE-coated pulleys in fertilizer plants prevent ammonium salt adhesion and corrosion.

Logistics

Stainless steel head pulley in conveyor systems powers sorting lines, combining hygiene with magnetic metal removal from parcels.

Design

High-Traction Lagging

Ceramic pulley lagging increases friction to 0.4-0.6 (vs. steel 0.2), eliminating slippage. Every head drive pulley benefits from this upgrade.

Customizable Diameter

Diameters from 200-1800mm; larger sizes (≥1000mm) boost belt contact area by 40%, reducing tension requirements.

Corrosion & Wear Resistance

Optional ceramic pulley lagging (1500HV) for abrasive ores extends the head pulley in conveyor lifespan 300% over standard designs.

Advantage

Drums or Shells

Made of steel or other durable materials,it can absorb impact energy from material loading and resist bending deformation under belt tensions up to 8,000 kN/m (CEMA Standard).

Shafts

Made of cold drawn steel, it can ransmit torque from drive motor to the shell while resisting bending moments.

Bearings

Deep groove precision ball bearings support radial/axial loads and accommodate shaft misalignment.

Laggings

Ceramic pulley lagging enhances friction and protects the head drive pulley shell - critical for drive efficiency. Comapared with bare steel pulleys, it can increase drive efficiency by 15-25% .

Locking Assemblies

Prevent slippage >500 kN·m on the head pulley in conveyor even during magnetic surge loads.

End Discs

Welded to shell ends; reinforce structural integrity against radial forces.

Production

Intelligent Production Workshop

Hebei, May 1st , 2023, JUXIN is thrilled to announce the triumphant completion and utilization of its state-of-the-art 6,000 square meter intelligent production workshop.

Intelligent Idler Production Line

Hebei, June 1st, 2023,JUXIN announces the successful implementation of its state-of-the-art Intelligent Idler Production Line.

Certificate

Hot Tags: head drive pulley, China head drive pulley manufacturers, suppliers, factory, conveyor head drive pulley, cloth drying rope pulley, pulley hardware, Tail Drum Pulleys, conveyor return pulley, well pulley

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||