Introduction

Application

|

The unique design of the self-cleaning return idler is essential where standard rollers fail: Mining and AggregatesWhere a standard conveyor return idler clogs with mud or wet fines, our solution keeps the belt clean. Agriculture and CompostingThe ideal choice for handling sticky manure, compost, or other organic materials that cause buildup. Cement and Concrete ProductionPrevents the accumulation of wet, abrasive materials that can destroy a conventional conveyor return idler. Recycling and Waste ManagementAs a trusted conveyor idler supplier, we recommend this for sorting lines where muddy debris is common.

|

Design

Automated and Automatic Cleaning

The unique spiral or disc-based design actively sheds sticky and fine materials off the belt and the idler itself, keeping the conveyor return idler clean.

Eradicate Belt Mistracking

By preventing uneven buildup on the roller, this specialized conveyor return idler ensures the belt stays centered, reducing edge damage.

Extend Conveyor Belt Life

When self-cleaning return idlers are installed, there is a great deal less abrasive wear on them, so the life of your most expensive conveyor component is greatly extended.

Good Bearing Capacity and Strength

Built with anti-abrasive rubber rings and corrosion-resistant materials, this conveyor return idler withstands harsh environments.

Advantage

Rubber Disc or Steel Spiral

It is the working part. Its benefit is that a vibration and a screw-like motion generate force to the material physically and eject it.

Central Steel Tube

This provides the rigid foundation for the entire conveyor return idler. Its benefit is that it guarantees structural integrity and deflection under loading.

Sealed Bearing Assembly

This is a critical feature of any quality self-cleaning return idler. Our multi-labyrinth seal design is a benefit that offers us the highest level of protection against dust and moisture, which ensures a long service life.

High-tensile steel shaft

This is more supportive and stronger. It has an advantage in that it is resistant to high operation of belt tension and impact may occur without failure.

Precision Welded Housings

These housings hold the bearing assembly in the tube. The advantage is their precision and strength, ensuring the perfect alignment and longevity of the entire conveyor return idler.

Production

Intelligent Production Workshop

Hebei, May 1st, 2023, JUXIN is thrilled to announce the triumphant completion and utilization of its state-of-the-art 6,000 square meter intelligent production workshop.

Intelligent Idler Production Line

Hebei, June 1st, 2023, JUXIN announces the successful implementation of its state-of-the-art Intelligent Idler Production Line.

Certificate

Hot Tags: self-cleaning return idler, China self-cleaning return idler manufacturers, suppliers, factory, Garland Idler Roller, Carrying Idler Roller, carrying idlers for belt conveyor, Flat Return Idler, luff idlers, rubber disc impact conveyor idler

|

|

|||||||||||||

|

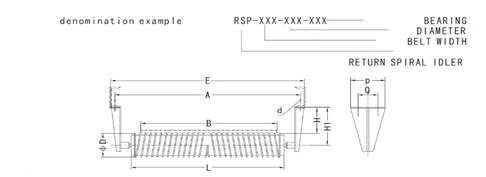

BE LT WI D T H |

MODEL |

R O LL E R |

BE ARI N G N o. |

E |

A |

H |

H 1 |

P |

Q |

d |

M A SS (K g ) |

||

|

MODE L |

D |

L |

|||||||||||

|

500 |

-050-89-204 |

SP R-89-204-600 |

89 |

600 |

204 |

792 |

740 |

55.5 |

100 |

145 |

90 |

M 12 |

16.6 |

|

650 |

-065-89-204 |

SP R-89-204-750 |

89 |

750 |

204 |

942 |

890 |

55.5 |

100 |

145 |

90 |

M 12 |

19.7 |

|

-065-89-205 |

SP R-89-205-750 |

205 |

18.4 |

||||||||||

|

-065-108-204 |

SP R-108-204-750 |

108 |

204 |

55.5 |

109.5 |

19.0 |

|||||||

|

-065-108-205 |

SP R-108-205-750 |

205 |

20.1 |

||||||||||

|

-065-108-305 |

SP R-108-305-750 |

305 |

20.4 |

||||||||||

|

800 |

-080-89-204 |

SP R-89-204-950 |

89 |

950 |

204 |

1142 |

1090 |

100 |

144.5 |

145 |

90 |

M 12 |

24.8 |

|

-080-89-205 |

SP R-89-205-950 |

205 |

23.2 |

||||||||||

|

-080-108-204 |

SP R-108-204-950 |

108 |

204 |

100 |

154 |

24.0 |

|||||||

|

-080-108-205 |

SP R-108-205-950 |

205 |

25.5 |

||||||||||

|

-080-108-305 |

SP R-108-305-950 |

305 |

25.7 |

||||||||||

|

-080-133-205 |

SP R-133-205-950 |

133 |

205 |

100 |

166.5 |

29.3 |

|||||||

|

-080-133-305 |

SP R-133-305-950 |

305 |

29.7 |

||||||||||

|

1000 |

-100-108-205 |

SP R-108-205-1150 |

108 |

1150 |

205 |

1342 |

1290 |

110 |

164 |

150 |

90 |

M 16 |

30.7 |

|

-100-108-305 |

SP R-108-305-1150 |

305 |

30.9 |

||||||||||

|

-100-108-206 |

SP R-108-206-1150 |

206 |

32.9 |

||||||||||

|

-100-108-306 |

SP R-108-306-1150 |

306 |

33.4 |

||||||||||

|

-100-133-205 |

SP R-133-205-1150 |

133 |

205 |

110 |

176.5 |

34.0 |

|||||||

|

-100-133-305 |

SP R-133-305-1150 |

305 |

34.4 |

||||||||||

|

-100-133-206 |

SP R-133-206-1150 |

206 |

36.3 |

||||||||||

|

-100-133-306 |

SP R-133-306-1150 |

306 |

36.7 |

||||||||||

|

-100-159-205 |

SP R-159-205-1150 |

159 |

205 |

110 |

189.5 |

40.1 |

|||||||

|

-100-159-305 |

SP R-159-305-1150 |

305 |

40.4 |

||||||||||

|

-100-159-206 |

SP R-159-206-1150 |

206 |

42.4 |

||||||||||

|

-100-159-306 |

SP R-159-306-1150 |

306 |

42.8 |

||||||||||

|

1200 |

-120-108-205 |

SP R-108-205-1400 |

108 |

1400 |

205 |

1592 |

1540 |

120 |

174 |

150 |

90 |

M 16 |

36.1 |

|

-120-108-305 |

SP R-108-305-1400 |

305 |

36.3 |

||||||||||

|

-120-108-206 |

SP R-108-206-1400 |

206 |

38.7 |

||||||||||

|

-120-108-306 |

SP R-108-306-1400 |

306 |

39.3 |

||||||||||

|

-120-133-205 |

SP R-133-205-1400 |

133 |

205 |

120 |

186.5 |

40.9 |

|||||||

|

-120-133-305 |

SP R-133-305-1400 |

305 |

41.3 |

||||||||||

|

-120-133-206 |

SP R-133-206-1400 |

206 |

43.7 |

||||||||||

|

-120-133-306 |

SP R-133-306-1400 |

306 |

44.1 |

||||||||||

|

-120-159-205 |

SP R-159-205-1400 |

159 |

205 |

120 |

199.5 |

48.3 |

|||||||

|

-120-159-305 |

SP R-159-305-1400 |

305 |

48.6 |

||||||||||

|

-120-159-206 |

SP R-159-206-1400 |

206 |

51.0 |

||||||||||

|

-120-159-306 |

SP R-159-306-1400 |

306 |

51.3 |

||||||||||

|

1400 |

-140-108-205 |

SP R-108-205-1600 |

108 |

1600 |

205 |

1800 |

1740 |

130 |

184 |

150 |

90 |

M 16 |

40.6 |

|

-140-108-305 |

SP R-108-305-1600 |

305 |

40.8 |

||||||||||

|

-140-108-206 |

SP R-108-206-1600 |

206 |

43.5 |

||||||||||

|

-140-108-306 |

SP R-108-306-1600 |

306 |

44.1 |

||||||||||

|

-140-133-205 |

SP R-133-205-1600 |

133 |

205 |

130 |

196.5 |

45.4 |

|||||||

|

-140-133-305 |

SP R-133-305-1600 |

305 |

45.9 |

||||||||||

|

-140-133-206 |

SP R-133-206-1600 |

206 |

48.6 |

||||||||||

|

-140-133-306 |

SP R-133-306-1600 |

306 |

49.0 |

||||||||||

|

-140-159-205 |

SP R-159-205-1600 |

159 |

205 |

130 |

209.5 |

53.8 |

|||||||

|

-140-159-305 |

SP R-159-305-1600 |

305 |

54.1 |

||||||||||

|

-140-159-206 |

SP R-159-206-1600 |

206 |

56.8 |

||||||||||

|

-140-159-306 |

SP R-159-306-1600 |

306 |

57.2 |

||||||||||